Home / News / Industry News / Aluminum alloy die casting is a mainstream process in the die casting industry.

Aluminum alloy die casting is a mainstream process in the die casting industry.

Nov.24,2022

Aluminum Alloy Die Casting Parts

Whether you're looking for automotive parts, electronic housings, or water craft parts, aluminum alloy die casting can be used for a wide range of applications. The material can also be used to create a variety of shapes, from complex and intricate forms to simple ones. Aluminum is highly machinable, and it also has a large electrical conductivity. It's also corrosion resistant in aqueous environments. It's often used in applications where other metals would rust.

Aluminum alloy die casting is a mainstream process in the die casting industry. It's used in a wide range of industries, including automobile manufacturing, power construction, and landscaping. It's also used to produce a variety of precision instruments and components.

Aluminum is a very strong metal, which makes it ideal for die casting. It's also corrosion-resistant in the atmosphere, and it can form several compounds when exposed to chemicals. Aluminum is also known for its high electrical conductivity, making it ideal for electronics. It also has excellent plasticity, which allows for easy casting into complex shapes.

Aluminum alloy die casting is a process that's commonly used in the automotive industry. Automobile manufacturers are developing in the direction of lightweight, high-quality, and energy-saving products. New energy cars are also becoming popular, and the structural components of these cars often need to be manufactured using a die-casting process.

Aluminum alloy die casting requires a small crystallization temperature range and a small shrinkage coefficient. This helps to reduce post machining, as well as reduces the number of parts that need to be cast. It also helps to create a strong product with a smooth finish. Compared with other casting processes, aluminum alloy die casting requires fewer machining operations, which can save time and labor. It also has a high density, making it easy to work with.

A variety of surface finishing options can be used to improve the performance of aluminum alloy die casting parts. This includes chrome plating, which forms a thicker layer that can improve the functionality of die casts. It's also possible to electroplate a stronger material onto a die cast to improve its performance.

Another option for aluminum alloy die casting parts is to use cast inserts. These inserts can be used to improve the process, improve the strength of the part, or increase the thickness of the part. Cast inserts are also used to enhance the properties of thick-walled pipes.

Wall thickness is a major consideration in aluminum alloy die casting. It's important to make sure that the wall thickness is uniform. Too thin a wall can result in shrinkage porosity, which can make it difficult to fill the casting's surface. The wall thickness also affects the shrinkage holes that are formed. A uniform thickness also prevents the disadvantages of forging ground stress.

The wall thickness also determines the draft angle of the die. It's important to have a reasonable draft angle, as this will prevent surface scratches and extend the life of the mold. The draft angle also varies with the type of alloy that is being used.

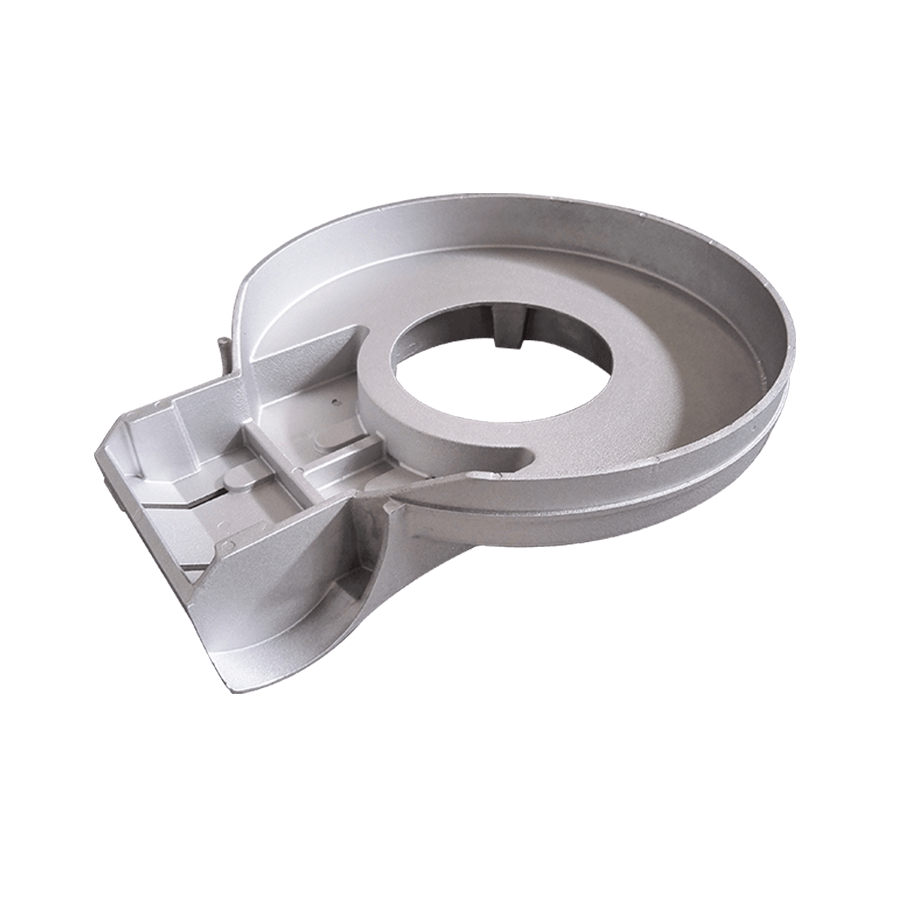

Sweeper Main Disk

Casting process:Low-pressure casting

Approximate weight:22kg

Approximate size:φ550x680

Application:Clean sweeper

简体中文

简体中文 English

English Español

Español Deutsch

Deutsch عربى

عربى