Home / News / Industry News / Aluminum Alloy Sand Casting Parts: The Key to Streamlining Your Production Process

Aluminum Alloy Sand Casting Parts: The Key to Streamlining Your Production Process

Jul.12,2023

In the world of manufacturing, efficiency and cost-effectiveness are paramount. Companies are constantly seeking ways to optimize their production processes while maintaining high-quality standards. One solution that has gained significant traction is the utilization of aluminum alloy sand casting parts. These versatile components offer numerous benefits that can streamline your production process and deliver impressive results.

Sand casting is a widely used manufacturing method for producing complex metal parts. It involves creating a mold from compacted sand and pouring molten metal into it. The mold is then removed once the metal has solidified, leaving behind a finished part. Aluminum, with its excellent casting properties, has become a popular choice for sand casting.

So, how can aluminum alloy sand casting parts help streamline your production process? Let's delve into the key advantages they offer:

Versatility: Aluminum alloy sand casting allows for the production of intricate and complex parts with great accuracy. The method is highly versatile and can accommodate a wide range of part sizes and shapes. Whether you require small, intricate components or larger, more robust parts, aluminum sand casting can meet your needs.

Cost-effectiveness: Aluminum is a cost-effective material compared to other metals used in casting processes. The raw material cost is lower, and the casting process itself is relatively inexpensive. Moreover, sand casting eliminates the need for complex tooling, reducing upfront costs significantly. This affordability makes aluminum sand casting an attractive option for both small-scale manufacturers and large industrial operations.

Lightweight and Durable: Aluminum alloys possess an impressive strength-to-weight ratio. This characteristic makes them ideal for industries where weight reduction is essential, such as automotive, aerospace, and consumer electronics. By utilizing aluminum alloy sand casting parts, you can achieve lightweight designs without compromising on durability and structural integrity.

Excellent Thermal Conductivity: Aluminum alloys exhibit excellent thermal conductivity, enabling efficient heat transfer. This property is advantageous for components that need to dissipate heat quickly, such as engine blocks, heat exchangers, and electronic enclosures. By incorporating aluminum alloy sand casting parts into your production, you can enhance the performance and reliability of your products.

Quick Turnaround Time: Sand casting is a rapid manufacturing process, allowing for faster production compared to other casting methods. The simplicity of the mold creation process and the ease of casting aluminum alloys enable shorter lead times, ensuring that you can meet demanding production schedules. This agility can give you a competitive edge in the market and improve customer satisfaction.

Design Flexibility: Aluminum alloy sand casting allows for intricate designs with various surface finishes. The sand molds can be easily customized to meet specific design requirements, giving you the freedom to create complex geometries, undercuts, and fine details. This versatility enables innovative product designs and supports your manufacturing objectives.

Sustainability: Aluminum is a highly recyclable material, with a recycling rate that surpasses most other metals. Utilizing aluminum alloy sand casting parts promotes sustainability and reduces environmental impact. The ability to recycle and reuse aluminum significantly lowers energy consumption and greenhouse gas emissions, aligning with the growing emphasis on eco-friendly manufacturing practices.

In conclusion, aluminum alloy sand casting parts offer a myriad of advantages that can streamline your production process. From versatility and cost-effectiveness to lightweight design and quick turnaround time, these components provide the foundation for efficient and high-quality manufacturing. By leveraging the benefits of aluminum alloy sand casting, you can optimize your operations, reduce costs, and deliver superior products to your customers. Embrace the power of aluminum casting and unlock the potential of your production process.

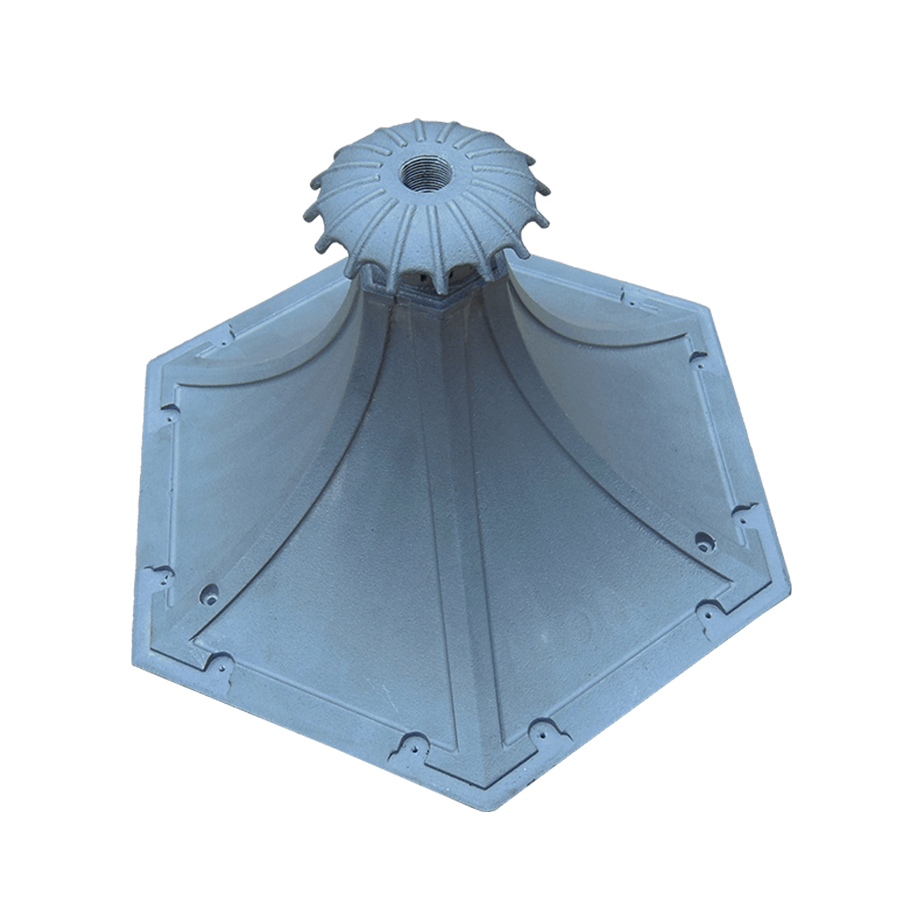

Casting process:Sand-cast

Approximate weight:6.8kg

Approximate size:320x320x280

Application:Lighting Accessories

简体中文

简体中文 English

English Español

Español Deutsch

Deutsch عربى

عربى