Home / News / Industry News / How Are Lamp Parts Cast and Assembled?

How Are Lamp Parts Cast and Assembled?

May.25,2023

The art of lampmaking involves various manufacturing processes to create functional and aesthetically pleasing lighting fixtures. One crucial aspect of this process is the casting and assembly of lamp parts. This essay explores the techniques and steps involved in casting lamp parts, highlighting the intricate craftsmanship required to bring these components to life.

What materials are used in casting lamp parts?

To cast lamp parts, a range of materials can be utilized. Common choices include metals like brass, bronze, and aluminum, which offer durability and malleability. Each material brings unique characteristics and finishes to the final product, allowing for customization based on design preferences and functional requirements.

What is the casting process for lamp parts?

The casting process begins with creating a mold that will shape the lamp part. Two main methods are commonly used: sand casting and investment casting. Sand casting involves creating a mold using compacted sand, while investment casting utilizes a wax model surrounded by a ceramic mold. Once the mold is prepared, the chosen material is melted and poured into the mold, allowing it to solidify and take the desired shape.

How are cast lamp parts finished and refined?

After the casting process, the newly formed lamp parts undergo several finishing techniques to achieve their desired appearance. This may involve removing excess material, such as gates and risers, through cutting or grinding. Next, surface treatments like polishing, sandblasting, or electroplating are applied to enhance the visual appeal of the parts. These finishing touches give the lamp parts a refined and professional look.

How are cast lamp parts assembled into functional fixtures?

Once the individual lamp parts have been cast and finished, they are assembled to create the final lighting fixture. This involves connecting the various components, such as the base, stem, socket, and shade holder, using appropriate fasteners and techniques. Depending on the design and complexity of the lamp, additional electrical wiring and socket installation may be required to ensure functionality and safety.

What considerations are important during the casting and assembly process?

Throughout the casting and assembly process, several factors need careful consideration. Precision and attention to detail are crucial to ensure that all components fit together seamlessly. Moreover, adherence to safety standards and regulations is essential, particularly regarding electrical connections and stability. Balancing aesthetics, functionality, and durability is a key aspect of creating high-quality cast lamp parts.

The casting and assembly of lamp parts involve a meticulous and skilled process to create functional and visually appealing lighting fixtures. By understanding the materials used, the casting techniques employed, and the necessary finishing and assembly steps, one gains insight into the craftsmanship behind these essential components. The artistry and technical precision involved in casting lamp parts contribute to the beauty and functionality of the final product, enhancing the ambiance of our living spaces.

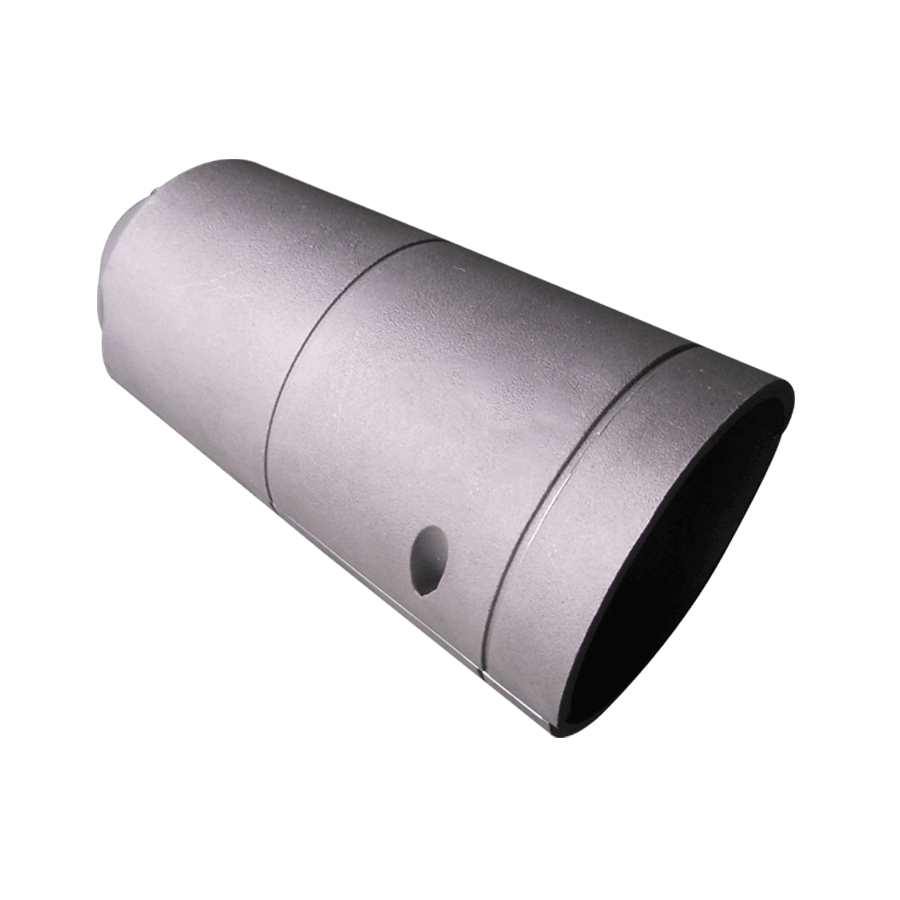

Casting process:Gravity casting

Approximate weight:1.2kg

Approximate size:φ140x180

Application:Street light accessories

简体中文

简体中文 English

English Español

Español Deutsch

Deutsch عربى

عربى