Home / News / Industry News / Why Aluminum Alloy Sand Casting Parts Are the Future of Manufacturing

Why Aluminum Alloy Sand Casting Parts Are the Future of Manufacturing

Mar.15,2023

Aluminum alloy sand casting is a manufacturing process that has been around for centuries, but it is now more relevant than ever. The process involves pouring molten aluminum alloy into a sand mold to create a desired shape. The result is a strong and lightweight part that can be used in a wide range of applications. In this article, we will explore why aluminum alloy sand casting parts are the future of manufacturing.

Lightweight and Strong

One of the primary benefits of using aluminum alloy sand casting parts is their strength-to-weight ratio. Aluminum is a lightweight metal, but it is also very strong. This makes it an ideal choice for applications where weight is a concern, such as in the aerospace and automotive industries. By using sand casting, manufacturers can create complex shapes with thin walls that are both strong and lightweight.

Versatile and Customizable

Another advantage of aluminum alloy sand casting is its versatility. The process can be used to create parts of all shapes and sizes, from simple to complex. It is also highly customizable, allowing manufacturers to create parts that meet specific requirements. This makes it an ideal choice for a wide range of industries, including aerospace, automotive, medical, and more.

Cost-Effective

Aluminum alloy sand casting is also a cost-effective manufacturing process. The raw materials are relatively inexpensive, and the process itself is efficient and fast. This means that manufacturers can produce high-quality parts at a lower cost than other manufacturing processes. Additionally, the molds used in sand casting can be reused, which further reduces costs.

Environmentally Friendly

In today's world, environmental concerns are more important than ever. Aluminum alloy sand casting is an environmentally friendly manufacturing process. The sand used in the process is natural and can be reused, and the aluminum alloy used is recyclable. This means that there is less waste produced during the manufacturing process, and the end product is sustainable.

Short Lead Times

Finally, aluminum alloy sand casting parts have short lead times. The process is fast and efficient, which means that manufacturers can produce parts quickly. This is particularly important in industries where time is of the essence, such as the aerospace and automotive industries.

In conclusion, aluminum alloy sand casting parts are the future of manufacturing. They are lightweight and strong, versatile and customizable, cost-effective, environmentally friendly, and have short lead times. These benefits make them an ideal choice for a wide range of industries, and they will continue to play an important role in the future of manufacturing.

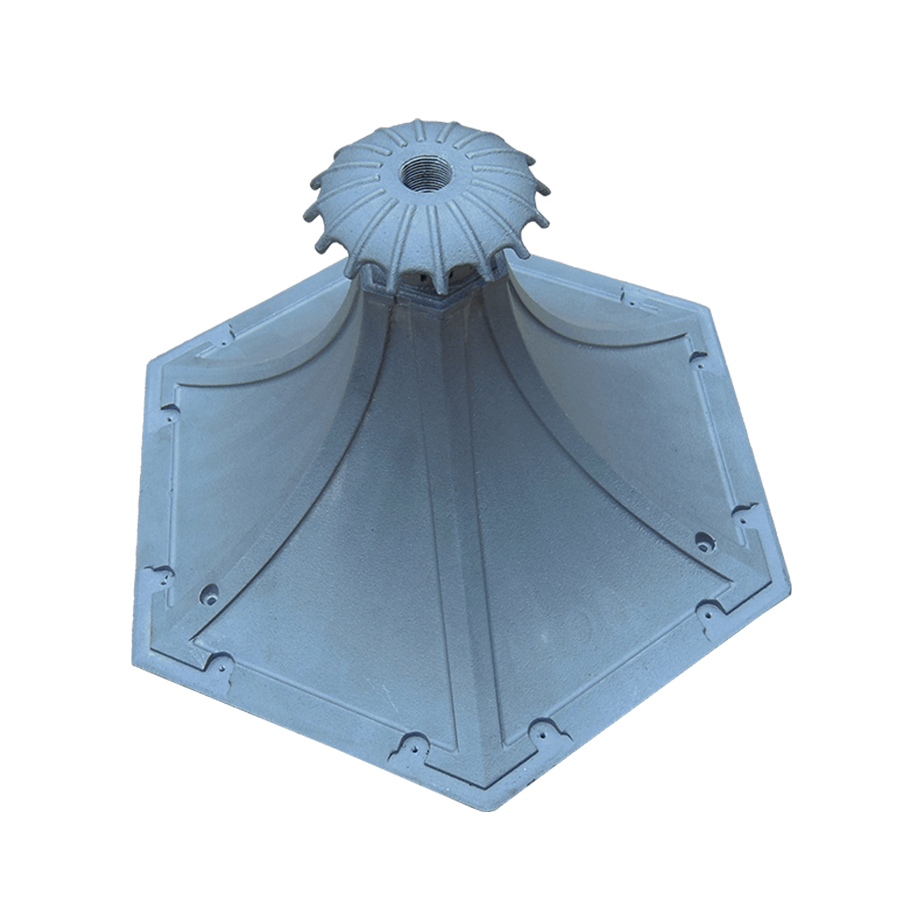

Casting process:Sand-cast

Approximate weight:6.8kg

Approximate size:320x320x280

Application:Lighting Accessories

Casting process : Sand-cast

Approximate weight : 6.8

Approximate size : 320x320x280

Application: Lighting Accessories

简体中文

简体中文 English

English Español

Español Deutsch

Deutsch عربى

عربى