Home / News / Industry News / Advantages of Choosing an Aluminum Alloy Part

Advantages of Choosing an Aluminum Alloy Part

Feb.11,2022

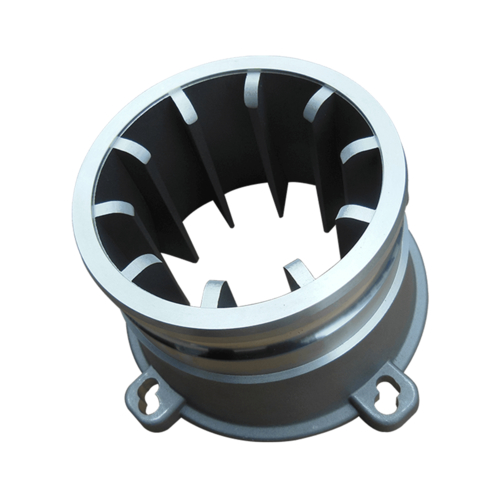

If you're in need of an aluminum alloy part, you've come to the right place. The company's shipping processes are fast and efficient. You can count on them to get your part to you quickly, so you can start your project and keep your plane in the air. There are a number of reasons to use aluminum alloy parts. They're lightweight and easy to machine, and they're perfect for airplane parts that have to be exposed to harsh environments.

The primary alloying element of aluminum is manganese. These alloys have moderate strength and excellent corrosion and heat resistance, and are useful for parts in the aerospace and automotive industries. They are also durable and meet or exceed all safety regulations. They're also ideal for welding filler. In addition, they're 100% recyclable. And because they're so lightweight, they're easy to machine and extrude. Besides their lightweight and corrosion-resistant qualities, these metals are also great for welding.

Listed below are some of the properties and benefits of aluminum. While they have similar physical properties, each alloy has slightly different physical characteristics. The 6061 alloy provides better surface finish and the 6063 alloy has stronger mechanical properties. Both are machinable and have excellent ductility. The table below highlights some of the common aluminum alloys, as well as their physical properties and characteristics. Each one offers its own advantages and disadvantages. You can find the right one for your needs with the help of this guide.

These metals have great tensile strength and are the most commonly used by extruders. They also have a wide range of applications and are ideal for die casting. They are strong and workable in annealed condition, so they can be fabricated using the most common methods. And because they are cast under lower pressure, they are easier to process and machinable. There are many advantages to choosing an aluminum alloy part, so make sure to shop around.

Among the many advantages of aluminum alloys, the most important is its cost-effectiveness. The material is 100 percent recyclable and requires less energy than other metals, and it's also eco-friendly. The advantages of aluminum over other metals include their low cost and higher quality. These benefits make aluminum the preferred choice of manufacturers. The material can be molded and forged quickly and can withstand temperatures as low as -40°C without cracking.

The main difference between an aluminum alloy part and a metal part is its tensile strength. Its strength can be measured in tensile strength. Both types of materials are strong, but they differ slightly in their physical properties. An aluminum alloy part can withstand a lot of stress and should not deform when it is subjected to it. This is why it is important to choose the right type of aluminum.

简体中文

简体中文 English

English Español

Español Deutsch

Deutsch عربى

عربى